The Relationship Between Drag and Fuel Economy

|

| Lined up and ready to head out on track at the 2022 Green Grand Prix, an annual fuel economy competition held the Friday of opening weekend at Watkins Glen International. |

We all know that reducing drag can improve fuel economy.

It’s intuitive but can be proven mathematically: when your car has less force

acting against it, it takes less fuel (gas, diesel, or electric) to move. But

what is the exact relationship between aero drag and economy? Can we measure

it? Or predict it? Figuring this out can help us plan modifications to our cars

with the aim of improving economy, as well as tell us if fuel economy is an

accurate measure of changes in drag.

Rules of Thumb

You’ll see rules of thumb tossed about online which relate

drag and fuel mileage. A common one says, “For every 10% reduction in

aerodynamic drag, fuel economy will improve 5%.”

Is that accurate? Well, in a word: no, as we’ll see in just

a minute. And its origins are murky. Some people attribute it to GM

aerodynamicist Gino Sovran, but I have never been able to find the source of

this claim. As far as I know, this is one of those “rules” that sprang up

online and took on a life of its own, shared so frequently that it becomes

“fact.” (If you have a documented source, please send me a message—I would love

to know where this actually originated and its context!).

Quantifying the Relationship

Fortunately, the subject of fuel economy as it relates to

aerodynamics is one that is very important to the car industry, so it is

covered in just about every textbook on aerodynamics out there.

AJ Scibor-Rylski wrote about it in his Road Vehicle

Aerodynamics (1975). Some of his assumptions are unrealistic when we try to

apply his examples to modern cars.

|

| How unrealistic? This unrealistic. There hasn’t been a car this light on the American market in decades. |

More recently, RH Barnard wrote

about the relationship between aerodynamic drag and fuel consumption in Road

Vehicle Aerodynamic Design (2009). Using the example of a mid-size European

sedan with a 1.5L engine and CD = 0.35, he points out that any

reduction in fuel consumption will be proportional to the change in total drag force

at a steady speed, not the change in aero drag coefficient. (This is an

important distinction, as many online commenters try to use the 10%:5% rule

with CD rather than FD). Reduce the car’s drag

coefficient to 0.25, a 28% reduction, and you change the total drag force—which

includes aerodynamic and mechanical drag, remember—by only 22% at 75

mph, which decreases fuel consumption by the same percentage. Also keep in mind

that fuel consumption is not measured in MPG but its inverse, volume per

distance (usually L/100km, as most of the world outside the USA uses).

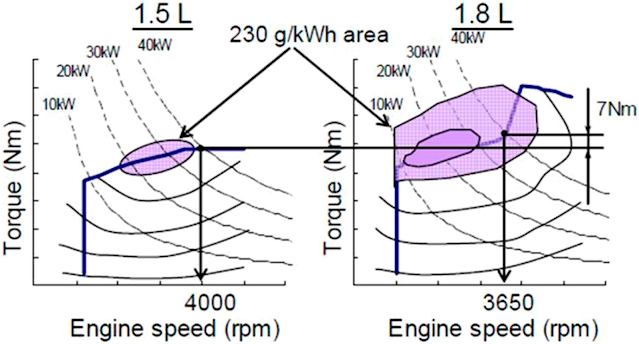

Barnard goes on to point out that

any “assumption of unaltered engine efficiency is not usually valid” and must

be taken into account; lower drag could keep the engine in a more- or less-efficient

part of its BSFC map. Further, the car’s drag coefficient at 0°

yaw is not its real-world coefficient, so to calculate a change in efficiency

we need its wind-averaged drag in the conditions it actually sees. And finally,

no one drives a car solely at a steady speed; even on a long highway trip it

must be accelerated and decelerated numerous times.

There’s another factor that both

authors leave out: as drag coefficient is decreased, aerodynamic drag becomes a

smaller and smaller proportion of the total force acting against the car and

thus the same percentage change in aero drag will have less of an effect. In other words, reducing CD

= 0.50 by 20% to 0.40 will have more effect on the overall drag force than

reducing CD = 0.25 by the same percentage to 0.20. So it matters how

low-drag your car is to begin with.

Energy

In physics and engineering,

problems that are difficult to solve by analyzing forces or momentum or motion

can often be figured out—sometimes quite simply—by looking at the change in

energy. In the case of an automobile, there are three energies associated with

its movement. First, there’s the energy it takes to accelerate the car of mass m to speed v—its

kinetic energy, K = ½ mv2. Second, there is the energy

expended to overcome the resistance of mechanical drag (or rolling

resistance)—this form of energy is called work, and it’s proportional to

the resistive force and the distance traveled, WR = FRd.

Finally, there is the energy required to overcome aerodynamic drag, which is

the same work as before but this time proportional to the aerodynamic drag

force, WA = FAd. K and WA are both

proportional to the speed of the car squared, while WR changes linearly with speed.

Looking at energy can clarify the

difficulty in trying to nail down a formula for relating aero drag changes to

fuel economy improvements. Any change in aero drag and its effect on

fuel economy will be overly sensitive to what speed you’re considering because

of the squared term. Since the

overall contribution of aerodynamic drag to the total energy requirement

changes with the square of speed, where aero drag can be the dominant energy expenditure at

high speeds, it will have more of an effect on fuel consumption at those high

speeds and less effect at lower speeds e.g. a 5% improvement at 80 mph which

turns into 3% at 60 mph might drop to 1% at 50 mph. Because of this, it is

impossible to issue a blanket rule such as “10% reduction in aero drag = 5%

improvement in fuel economy” without specifying the car’s drag area, its mass,

its coefficient of rolling resistance, its BSFC and gearing, and its exact

speed.

What Now?

So it seems the only confident

statement we can make regarding a broadly quantifiable relationship between

aerodynamic drag and fuel consumption as measured on the road is this: Reducing

drag should reduce consumption somewhere between the same percentage change and

zero.

That’s not very helpful. But even

if we can’t easily quantify a relationship between changes in fuel economy and

changes in aerodynamic drag, I think it is still a useful measure. If repeated

testing at high speeds and over long distances shows a reduction in fuel

consumed, that’s a pretty good indication that whatever change you’ve made to

your car has reduced its drag. Just don’t bother trying to use the percentage

change in consumption to figure out a percentage change in drag or to predict the

percentage change in fuel economy based on the change in drag; there’s too much

going on that you can’t account for on the road to make either of those

anywhere close to accurate. Try one of these methods to measure changes in drag

directly instead, especially if your goal is to optimize

aerodynamic modifications.

Comments

Post a Comment