Testing a Smooth Engine Undertray

When I investigated the effects of a splitter on my Prius, I discovered something unusual: gauge pressures on the stock engine undertray were a lot higher than I expected.

Julian Edgar’s Vehicle Aerodynamics: Testing, Modification & Development includes several examples of engine undertrays with measured

pressures much less than atmospheric. My test showed that the Prius undertray

was developing pressures at atmospheric or higher. What was going on?

|

| Gauge pressure at 80 kph. Left: no splitter. Center: with splitter. Right: difference. |

|

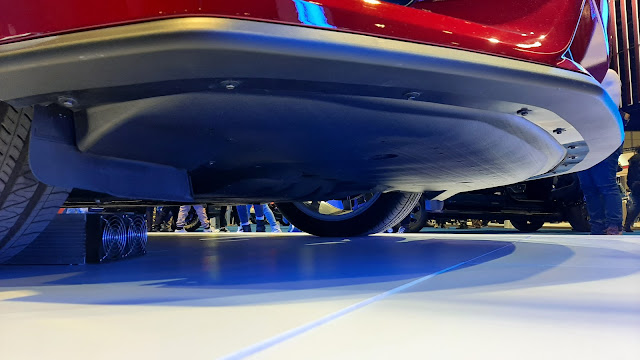

| 2023 Honda HR-V |

|

| 2023 Nissan Ariya |

|

| 2023 Volkswagen ID4 |

|

| 2024 Ford Mustang GT |

And here’s mine, the stock undertray on a 3rd-generation Prius:

|

|

Stock

Undertray |

Smooth

Undertray |

Difference |

|

Front |

+20 Pa |

0 Pa |

-20 Pa |

|

Center |

+50 Pa |

+ 20 Pa |

-30 Pa |

|

Rear |

+40 Pa |

-10 Pa |

-50 Pa |

Comments

Post a Comment