Systems

engineering has a long history despite not becoming a formalized discipline

until after World War 2. What is systems engineering? Basically, it is the overarching

management of large or complex design projects: identification of customer

needs and market, development of requirements, control of subsystems and

integration, etc. For example, how is a modern airliner built? First, a

preliminary design study is completed, often lasting a few years, before

requirements are finalized and the basic design of the vehicle is established;

then, detailed design work can begin, which usually takes several years to

complete. Finally, verification and certification testing are completed, after

which the vehicle can be released. All these processes are overseen by systems engineers.

|

| The evolution of automotive systems engineering in one picture. As time goes on, the product is more technically complex and requires more rigorous control of various inputs in the design process. |

Similarity

Analysis

One of the

starting points for basic design of a new vehicle is similarity analysis,

the evaluation of existing vehicles that serve the same market or purpose as

the proposed new design. In similarity analysis, one must identify important

parameters or characteristics of competitor vehicles; oftentimes, these are proprietary

and must be estimated. We have spent a considerable amount of time practicing

this with aerospace vehicles in my Systems Designs class this semester, but

since my primary interest is in ground vehicles I started collecting

information on production automobiles in a spreadsheet to see what I could

learn.

Specifically,

after looking at aerodynamic and dimension data for a bunch of cars, and after this

topic was brought up in class last week, I started to wonder: can we answer the

question of whether a 100-mpg gas-powered car—long the “holy grail” of the auto

industry—is possible by conducting a basic similarity study?

You’ve

probably heard of the concept of the 100-mpg car before, since it was

popularized by the “Automotive X-Prize” competition that ran for several years

about a decade ago. Nothing ultimately came of that competition—the mass-produced 100-mpg gas

car has never been a reality. Let’s find out why.

Methodology

In order

to try and answer this question, I first identified what data I would need. To

do this, we ask: “What drives fuel consumption in a car?” A good starting point

to answer a question like this is a free body diagram, a

visual plot of the forces acting on a body and their directions. Do this for a

car in motion and you will figure out that fuel consumption (which is really a

proxy for energy usage) is driven by rolling drag and aerodynamic drag. What

are the primary factors driving these two forces? Weight, drag area, and

velocity have the largest influence, with secondary drivers being coefficient

of rolling resistance, air density, gravitational acceleration (we usually

neglect it in calculations, but this varies with altitude), elevation changes,

and atmospheric conditions (especially wind). For simplicity of analysis, some

of these secondary effects can be ignored; here, I will assume negligible elevation

changes, air density and gravitational acceleration at sea level, and no winds.

You may

have read in car reviews that a manufacturer says their new car model uses “X

horsepower at Y mph.” How is this calculated? Power is given by the tractive

force exerted by a car multiplied by its velocity; in SI basic units this returns

power in watts (W) but standard units in automotive engineering are “horsepower”

(hp). At cruise, the tractive force required to maintain speed is the same as

the total resistive force acting on the car (since change in velocity is 0), or

the sum of rolling and aerodynamic drag. Aerodynamic drag is given by the

familiar equation…and

rolling drag by the weight multiplied by some coefficient of rolling

resistance, typically between 0.010 and 0.015 for a car tire (LRR tires being

on the low end and knobby off-road tires on the high end). To account for the

inertial moments of the rotating components of a car—wheels/tires, brakes,

axles, transmission gears, crankshafts, etc.—nominal weight is multiplied by a correction

factor. I have previously tried to calculate this for my car and arrived at an estimate of 2% of total mass; I will assume this correction factor for all the vehicles below. This gives rolling drag by Add these

two together and multiply by cruise speed et voilá: horsepower required.

To check the validity of this method, you can compare it against one of those

reported values from the auto magazines. For example, when the Volkswagen XL1

was released (in very limited numbers) back in 2014, it was widely reported

that VW said it required 8.3 hp to maintain 62 mph—still an absurdly low

number! VW’s press materials gave the weight, drag coefficient, and dimensions

of the XL1 so, using standard atmosphere, we can calculate required power with

our equation and check it against the reported value:

How about

that—exactly the same! In fact, this is probably how VW engineers calculated

the required horsepower. You can do the same for your car. (Note that I will include 150 lb driver weight in all calculations below; VW may not have done that, or they may have used a lower coefficient of rolling resistance).

Now, let’s

do this for a bunch of cars. Dimensions and weights are very easy to find for

any current car; manufacturers usually publish this right on their websites.

Only a handful of OEMs publish drag coefficients, however, and some are very

inconsistent about it, doing it for some of their cars and not others (*cough*

Toyota *cough*). However, after a couple days of intermittent searching and

procrastinating homework I was able to find reliable (as in, from a reputable

source—either the manufacturer directly or a reliable automotive news source

like Car & Driver) drag coefficients for about 30 cars, a fairly

broad selection of everything from economy cars to large trucks (mostly 2024 or

2025 model year, but I included older if the generation hasn’t changed, as well

as a 2006 Insight and 2013 Prius for reference). It was sometimes a surprise which

data manufacturers choose to include—for instance, Stellantis lists frontal

area in the specifications data of the 2022 Jeep Grand Cherokee! If you go

looking for this yourself, a good place to start is press packages from new car

introductions; often, aerodynamic data will be included in the info dump.

Then,

throw it all in a spreadsheet with the proper formulas and propagate it with calculated

values. You should get something that looks like this:

|

| Yes, I am a nerd who does this for fun and I fully embrace that. |

That’s a

lot of information, and very hard to glean anything about trends despite

organizing it by ascending cruise horsepower. I’ve written before that plotting

things visually helps to see what you’re interested in learning from the data. Let’s do that here.

Results

What

should we plot? Well, I’m interested in seeing how fuel economy trends with its

drivers, which I identified above as velocity, drag area, and weight. Since I’m

comparing these vehicles at constant cruise, velocity has been removed as a

variable, leaving weight and drag area. Let’s graph EPA highway fuel economy as

a function of each of those:

There are definite

trends here, although correlation is not as high as I would have hoped (R2

= 1 would mean the interpolated line crosses through every data point).

However, it’s clear that generally, as weight or drag area increase, EPA

highway fuel economy goes down.

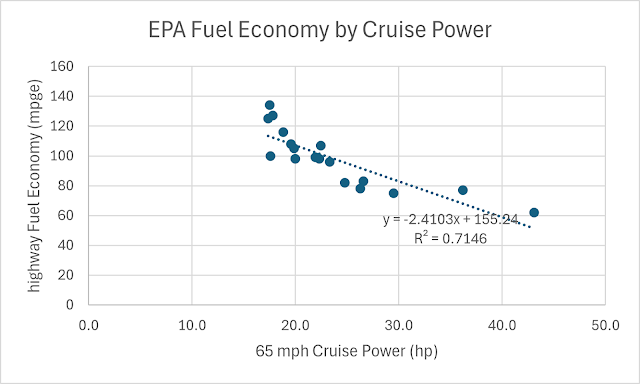

But

remember, drag area and weight each factor into the same parameter: cruise

power. What happens if we graph EPA highway fuel economy as a function of

required horsepower at cruise?

Now the

trend is even clearer, and correlation is higher: as required cruise horsepower

goes up, EPA highway fuel economy goes down.

Discussion

I’m not

surprised that the plots show this correlation between weight, drag area, cruise

power, and fuel economy; it’s exactly what we expect based on intuition. More

power required to go the same speed = more fuel required.

Much of

the variation can be explained by the fact that a variety of cars are

represented. For example, these two points:

…are the Toyota

GR86 and Nissan GT-R. While their weights and drag areas are fairly low, the

cars are optimized for track performance more than economical driving, with

things like shorter gearing helping acceleration but putting their engines in

higher-consumption parts of their fuel maps at cruise. On the other side, this

point:

…is the

2006 Honda Insight, still the lowest-drag car ever sold in the US. That car was

optimized in an entirely different way, specifically to get good fuel economy.

This is even more true of the XL1, which sits here on the plot (estimating its

highway cruise at 100 mpg, on the low end of what magazine reviews said it got;

this car was never sold in the US and consequently has no EPA rating):

Now, the

problem with the XL1 and original Insight is their optimization: both cars are

two-seaters, are made of lightweight but expensive materials, and do not have

the typical capabilities buyers generally expect in a car e.g. four doors, seating

for 5, sound insulation (XL1), etc. So, both cars were short-lived, did

not sell in large numbers (the XL1 by design), did not spawn imitators, and did

not have much lasting impact on car design. They’re really outliers here.

And that

leads me to conclude that we will never see a 100-mpg gas-powered car for sale

in the US. In order to achieve that, such a car would have to be very light

(increasingly hard with more mandated safety equipment now than even 10 years

ago), very small (which buyers consistently demonstrate they do not prefer, as

they have gravitated over the last several decades to larger and larger trucks and SUVs),

and very compromised in terms of what buyers want. To make a business case, a

new car can’t stray very far from the mainstream. Extrapolate the graphs above

to their y-axes and the intercept is only around 70 mpg on each of them. Of

course, in reality there is a hard weight limit somewhere, probably around 2000

lb based on production cars in the last half century. As we get nearer that

weight limit and some minimum drag area (a respected aerodynamicist told me

once that he thinks production cars will achieve CD = 0.20

and pretty much stop there), the only gains possible will be from increased

efficiency in the engine and drivetrain, and that is subject to physical

limits too. This tells me that, for a gas car that could be saleable

and is reasonably close to providing the same capabilities and user experience

as today’s cars, 100 mpg is simply not feasible.

Now, where

we do have 100-mpg gas-equivalent cars is in the electric market.

Due to the inherent efficiency advantage of electric motors compared to combustion

engines (which waste more than half the energy in the liquid fuel as unusable

heat), many EVs get the equivalent of 100 mpg or more. Plotting EPA economy as

a function of required cruise power (using the same methodology as above) but

this time for EVs might show us something interesting too.

Notice

that the high ends of both weight and cruise power are greater than on the ICE

graphs (the heaviest vehicle on each list is the Chevrolet Silverado, which has

both gas and electric versions), a consequence of EVs tending to be heavier

than their ICE counterparts due to their use of large batteries to provide

consumer-acceptable range and consequently requiring more power to sustain any

given speed. These plots suggest that weight must be kept low for EVs to

achieve best efficiency.

Thinking about

that led me to wonder if the proportion (percentage) of aerodynamic drag and

rolling drag would show any trends. Here are plots of the relative proportions

as functions of weight, drag area, and cruise power for gas cars and EVs

combined:

The last two charts don’t show much correlation; as drag area or required power

increase, there doesn’t appear to be any real trend in in the relative importance of

aero fraction versus rolling fraction. But that first chart does show a clear

trend: lighter cars tend to have a greater portion of their energy devoted to overcoming

aerodynamic drag—and so will benefit more from measures to reduce drag area

than weight. On the other hand, as cars get heavier a larger proportion of

their energy is used to overcome rolling drag—so these cars may benefit more

from measures to reduce weight. Again, we sort of know this intuitively but charting

a cross section of actual cars shows it objectively. That’s the lesson of

similarity analysis, and it echoes a sentiment I’ve shared on this site many

times before: don’t guess! Look at what’s actually going on.

|

| The 2014 Volkswagen XL1; you can see this example at the Lane Motor Museum in Nashville, TN. |

Comments

Post a Comment